Scope

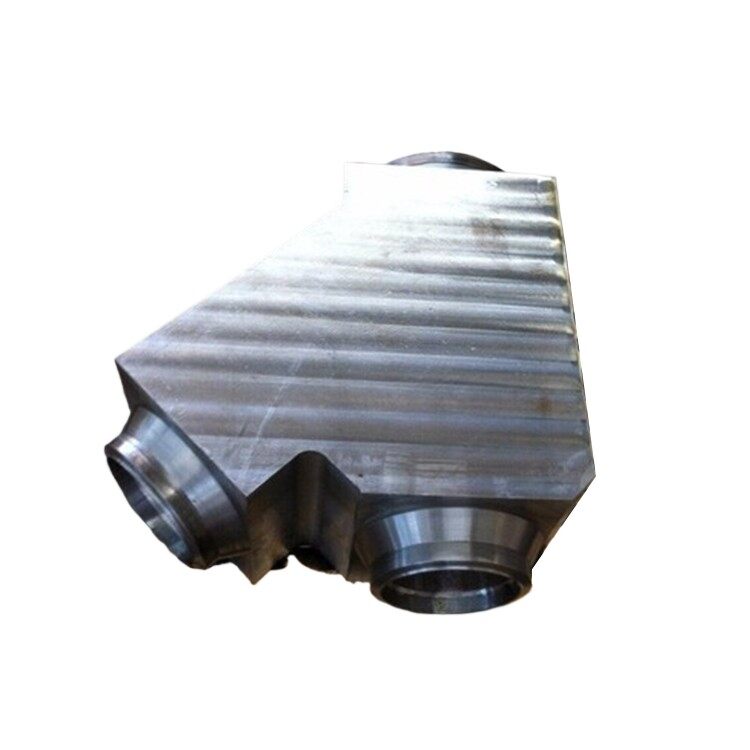

ASTM A105 forged fittings thiab ASME SA105 forged fittings npog seamless forged carbon steel piping Cheebtsam rau siv nyob rau hauv siab systems ntawm ambient thiab high-temperature kev pab cuam.

Flanges, fittings, li qub thiab ntau lwm qhov chaw txiav txim rau cov neeg siv khoom loj lossis rau cov qauv kev lag luam xws li MSS, ASME thiab API specification yog suav nrog hauv qhov.

Forgings rau qhov kev qhia tshwj xeeb no tsuas yog txwv rau 10,000 lbs.

Vuam

Cov khoom no tuaj yeem welded. Cov txheej txheem vuam yuav tsum ua raws li ASME Boiler thiab Pressure Vessel Code Tshooj IX.

Kev kho cua sov

Kev kho cua sov tsis yog qhov yuav tsum tau ua tshwj tsis yog rau flanges saum Chav Kawm 300, flanges ntawm cov qauv tsim tshwj xeeb uas qhov kev tsim siab lossis tsim qhov kub tsis paub thiab rau cov khoom tshaj 4 "NPS thiab siab dua Chav Kawm 300. Thaum kho cua sov yog xav tau, annealing, normalizing, normalize thiab temper, normalize thiab quench thiab tempering yuav tsum tau siv txoj kev.

Forging

Qhov no alloy yog forged ntawm 1,700 degrees Fahrenheit thiab 2,200 degrees Fahrenheit, ua raws li los ntawm quenching thiab tempering.

Annealing

Forged qhov chaw raug tso cai kom txias kom qis dua 1, 000 degrees Fahrenheit ua ntej rov ua kom sov li ntawm 1,550 degrees Fahrenheit thiab 1,700 degrees Fahrenheit. Cov cua sov qeeb qeeb ua raws li.

Tshuaj muaj pes tsawg leeg

|

Element |

Muaj pes tsawg leeg %, Note C |

|

Cov pa roj carbon |

35 max |

|

Manganese |

.60-1.05 |

|

Phosphorus |

035 max |

|

Sulfur |

040 max |

|

Silicon |

.10-35 |

|

Tooj |

.40 max, note A |

|

Nickel |

.40 max, note A |

|

Chromium |

.30 max, note A, B |

|

Molybdenum |

.12 max, note A, B |

|

Vanadium |

.08 max, note A |

|

Faj seeb A – Cov lej ntawm tooj liab, npib tsib xee, chromium, molybdenum thiab vanadium yuav tsum tsis pub tshaj 1.00% |

|

Mechanical Properties

|

Tensile |

70 ksg, m |

|

Yield, note A |

36 kwm, |

|

Elongation nyob rau hauv 2in, Basic yam tsawg kawg nkaus rau phab ntsa 5/16 "thiab tshaj, strip test |

30% |

|

Hardness |

187 HWB max |

|

Nco tseg A – Txiav txim siab los ntawm {{0}}.2% offset method lossis 0.5% extension-under-load method. Lwm txoj kev xeem muaj raws li teev hauv A105. |

|

Cov ntaub ntawv siv

- A266 / A266M Specification rau Carbon Steel Forgings rau Cov Khoom Siv Hluav Taws Xob

- A675 / A675M Specification rau Steel Bars, Carbon, Kub-Wrought, Tshwj xeeb Zoo, Mechanical Properties

- A696 Specification rau Steel Bars, Carbon, Kub-Wrought lossis Txias-Tiav, Tshwj Xeeb Zoo, rau Cov Khoom Siv Hluav Taws Xob

- A788/A788M Specification rau Steel Forgings, General Requirements

- A961 / A961M Specification rau Cov Kev Xav Tau Ntawm Cov Hlau Flanges, Forged Fittings, Valves, thiab Parts rau Piping Applications

- MSS Standard - SP 44 Txuj rau Hlau Yeeb Nkab Flanges

- B16.5 Dimensional Standards for Steel Pipe Flanges thiab Flanged Fittings

- B16.9 Wrought Hlau Buttwelding Fittings

- B16.11 Forged Steel Fittings, Socket Weld, thiab Threaded

- B16.34 Valves-Flanged, Threaded thiab Vuam kawg